OUR PRODUCT RANGE:

ELECTROMAGNETIC CHEMICAL DOSING PUMPS:

- FA SERIES

- FV SERIES

- FW SERIES

MECHANICALLY ACTUATED CHEMICAL DOSING PUMPS:

- FM Series

- FT Series

ELECTROMAGNETIC CHEMICAL DOSING PUMPS:

We specialize in designing tough and high performing range of Electromagnetic Dosing Pumps that are used to dose the fluid into the medium with defined volume and accuracy. V Dose Pumps are compact, good aesthetics and cost effective. Our Chemical Dosing pumps finds application in Chemical feed system for dosing Softeners, Cleansing Agents, Acids and Caustics. Glass filled Polypropylene body gives better Chemical resistance and longevity.

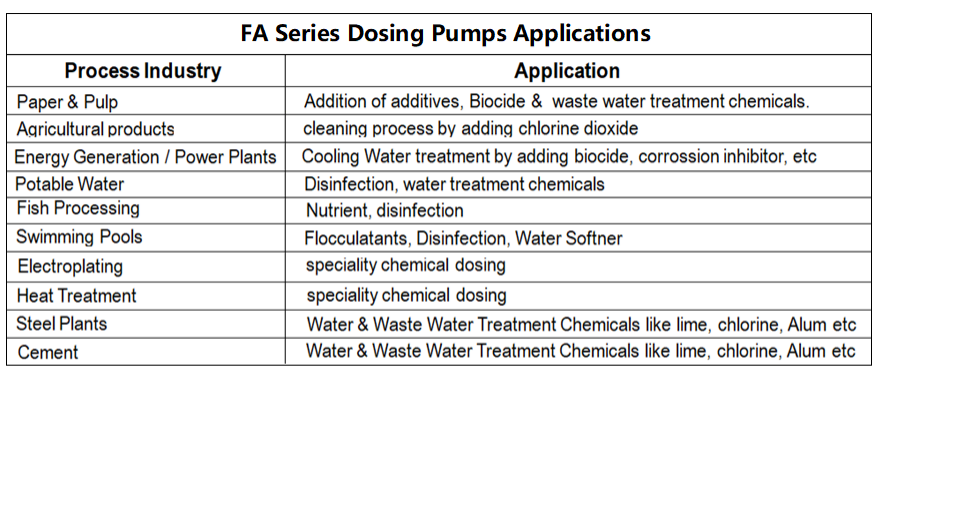

FA Series:

Series FA - Solenoid-driven Metering Pump for injecting liquid media in Water Treatment and Chemical Process.

FEATURES:

- Solenoid driven aided by innovative pulsar circuitry with low/high voltage protection.

- Glandless & Leakage free diapharm pumps.

- Adjustable injection frequency (120SPM).

- Adjustable volume displacement via stroke length adjustment.

- External proportional control with high turn down ratio.

- Corrosion resistance GFPP housing.

- Unique spacer design for prevention of chemical entry to Drive end.

- Teflon faced EPDM diaphragm for long lasting.

- Suction lift upto 1.5 mWc. Repeatability & Steady state accuracy: + -3%

- Wetted parts with available material combinations PP, PTFE, PVC, Clear Acrylic, & Stainless steel suitable for dosing extensive range of chemicals.

- FA Series

CAPACITY RANGE:

100 ml to 30 LPH, 21 – 1 Kg/Sq.Cm (bar)

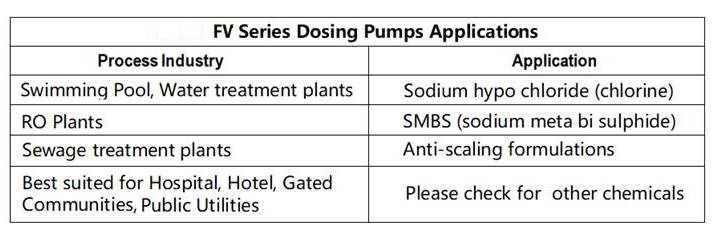

FV Series:

Series FV – Economical Solenoid-driven metering pump for metering liquid media to handle Industrial Water / Sewage Treatment Plants

FEATURES:

- Glandless & Leakage free diaphragm pumps

- Driven by innovative pulsar circuitry with low / high voltage protection

- Adjustable Injection Frequency (120 SPM)

- Corrosion resistant GFPP Housing (IP65).

- Liquid ends – Polypropylene.

- Low Power Consumption.

- Excellent proportional control.

- Modular design occupying less foot print.

- Optional Low Level facility with level Probe

- Optional air Bleed Valve

- FV Series

CAPACITY RANGE:

FV Series: 250ml to 12 LPH, 10 – 1 Kg/Sq.Cm (bar)

FW Series:

Series FW – Cost Effective Economical Solenoid-driven metering pump for metering liquid media exclusively for RO Plants.

FEATURES:

- Glandless & Leakage free diaphragm pumps

- Solenoid driven aided by Microprocessor based Pulser circuitry.

- Adjustable Injection Frequency (120 SPM)

- Corrosion resistant GFPP Housing (IP65).

- Unique spacer design for prevention of Chemical entry to drive end.

- Light weight.

- Liquid ends – Polypropylene.

- Low Power Consumption.

- Excellent proportional control.

- Modular design occupying less foot print.

- Teflon faced EPDM Diaphragm for long term service

- Suction lift upto 1 mWc

- Repeatability: + 3%

- Optional Low Level facility with level Probe.

- FW Series

CAPACITY 6 LPH @ 4 Kg/Sq.Cm

FW SERIES PUMPS ARE DESIGNED TO HANDLE INDUSTRIAL RO PLANTS Chemicals that can be dosed – Anti Scalent, SMBS, Alum, High pH Alkaline based Water Treatment Chemicals

MECHANICALLY ACTUATED CHEMICAL DOSING PUMPS

FTB series:

Variable Eccentric type, Motor driven Metering pumps with mechanically actuated diaphragms can be used almost universally in low pressure ranges.

FEATURES:

- Variable Eccentric design prevents Hydraulic Shock.

- Flow control adjustable manually during pump operation through stroke length adjustment knob.

- Optional External speed control via 0/4 – 20 mA standard signal with adjustable assignment of signal value to motor frequency through a VFD (optional).

- Wetted parts with available material combinations PP, PTFE, PVC,& Stainless steel suitable for dosing extensive range of chemicals.

- Teflon backed EPDM/PTFE Diaphragm for long lasting service.

- Available with 0.5 H.P & 1 HP Motor / Flameproof Motor.

Capacity range:

Upto 1175 LPH, 8 – 3.5 Kg/Sq.Cm (bar).

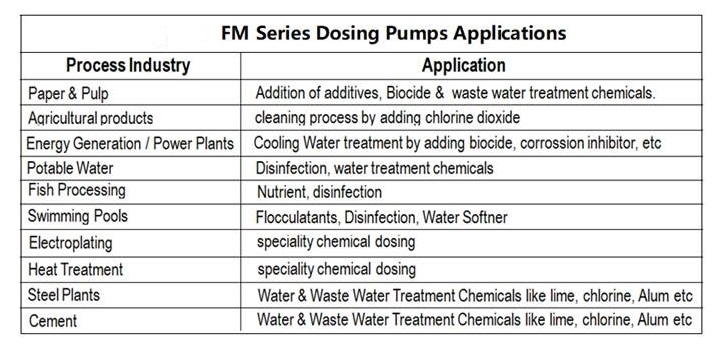

FM series:

Motor driven Metering pumps with mechanically actuated diaphragms can be used almost universally in low pressure ranges.

FEATURES:

- Flow control adjustable manually during pump operation through stroke length adjustment knob.

- Optional External speed control via 0/4 – 20 mA standard signal with adjustable assignment of signal value to motor frequency through a VFD (optional).

- Wetted parts with available material combinations PP, PTFE, PVC & Stainless steel suitable for dosing extensive range of chemicals.

- FM series available with 0.25H.P & 0.5 H.P Motor .

- (Input power: 415V/50Hz/3phase)* * 230V/50Hz/1Phase Motor is also available as an alternate

- Heavy duty Phosphor Bronze Gear for durability.

- Light Weight Aluminium body: Corrosion resistant painting.

Capacity range:

Upto 5 to 60 LPH, 12 – 6 Kg/Sq.Cm (bar)